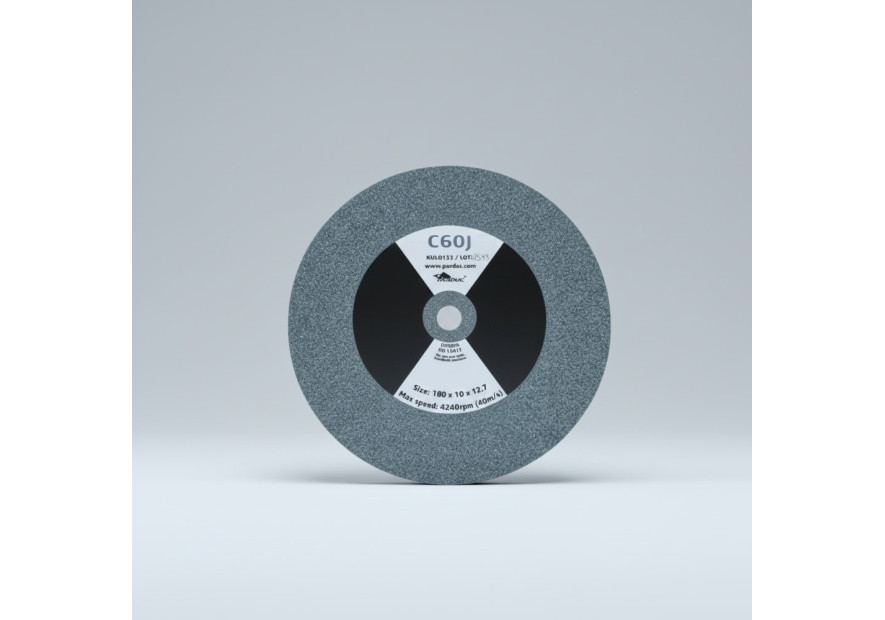

Grinding Wheel C60J

Compatible with Parduc M25 and Wissota. Fast, reliable skate sharpening

When it comes to professional skate maintenance, the Grinding wheel 180x10x12.7 C60J delivers consistent performance and efficiency every time you sharpen. This wheel is designed to be compatible with Wissota and M25 skate sharpeners, making it a popular choice for achieving professional-grade skate sharpening results.

Whether you run a busy rink, service skates for a team, or sharpen your own blades at home, this wheel is engineered for high-quality results that keep your edges precise and your workflow fast.

The Parduc C60J Advantage: overview and compatibility

The Parduc grinding wheel is a high-performance aftermarket solution designed to deliver precision and durability.

- Grit Size: 60 (C60). The C60 ceramic grinding wheelis built to balance material removal with smooth cutting action on steel skate blades.

- Dimensions: It is designed with a 180 mm diameter, 10 mm width, and 12.7 mm center hole.

- Material: High-Quality, Balanced Ceramic (Silicon Carbide - C). Silicon Carbide is an exceptionally hard abrasive material optimal for tackling extra hard skate blades.

- Compatibility: Aftermarket replacement for Wissota M/911 skate sharpening machines and original for Parduc M25

This robust design provides a predictable stroke after stroke for both hockey and figure skate blades

What is grit and why does it matter?

Grit refers to the abrasive particle size on a grinding wheel. Understanding grit levels is essential for sharpening quality and is specified by a number based on how many openings per inch the particles would pass through on a sieve.

The Basic Rule:

- Low grit number (e.g., 60): Indicates larger abrasive particles, which result in a coarser, faster-cutting wheel. This is ideal for heavy material removal.

- High grit number (e.g., 100): Indicates smaller abrasive particles, which result in a finer, smoother-cutting wheel. This is ideal for finish quality.

Choosing the right grit ensures the best combination of speed, finish, and blade control.

? Choosing your edge: Grit 60 vs. Grit 80 vs. Grit 100

The three most common grit options-60, 80, and 100-serve distinct purposes in professional skate maintenance.

Feature | 60 Grit (Parduc C60) | 100 Grit (Fine) | |

Material Removal Speed | Fastest. Aggressive and effective. | Medium-Fast. Good balance. | Slowest. Removes minimal material. |

Finish Quality | Excellent (Smooth/Shiny), especially with a ceramic/silicon carbide bond. | Very good. A sharp, functional edge. | Finest/Mirror finish. Smoothest and cleanest. |

Best Use Cases | Heavy Correction: Fixing damaged blades, profiling, or sharpening extra hard steel | Routine Maintenance: The standard, general-purpose wheel for most daily sharpening needs | Fine Finishing: Post-sharpening touch-ups or achieving a mirror-like edge |

The C60 grinding power

The C60-grit abrasive sits in the medium-to-coarse range. This coarser grit cuts more aggressively and efficiently, helping you complete sharpening tasks faster without sacrificing control or edge quality31. For many skate technicians, this balance between cutting speed and effective sharpening performance is exactly what is needed for quick turnaround and fewer passes.

Final recommendation for sharpening pros

Your optimal grit depends entirely on your sharpening volume and the condition of the blades you service.

- Choose Grit 60 (Parduc C60J) if you frequently encounter severely damaged, nicked, or neglected blades. It is also the ideal choice if you are working with modern, extremely hard stainless steel.

- Choose Grit 80 if you need an all-around wheel for standard, routine sharpening, as it gives the best overall results for most users.

- Choose Grit 100 if your primary goal is an absolute mirror-like finish and minimal material removal, often used for an ultra-fine, final finishing pass.

The Parduc 180x10x12.7 C60 is specifically marketed for its superior ability to handle tough, hard blades while still delivering an "exceptionally smooth and shiny finish". This makes it the ideal choice for technicians demanding high material removal power without sacrificing the final edge quality.